N.A. Woodworth Diaphragms

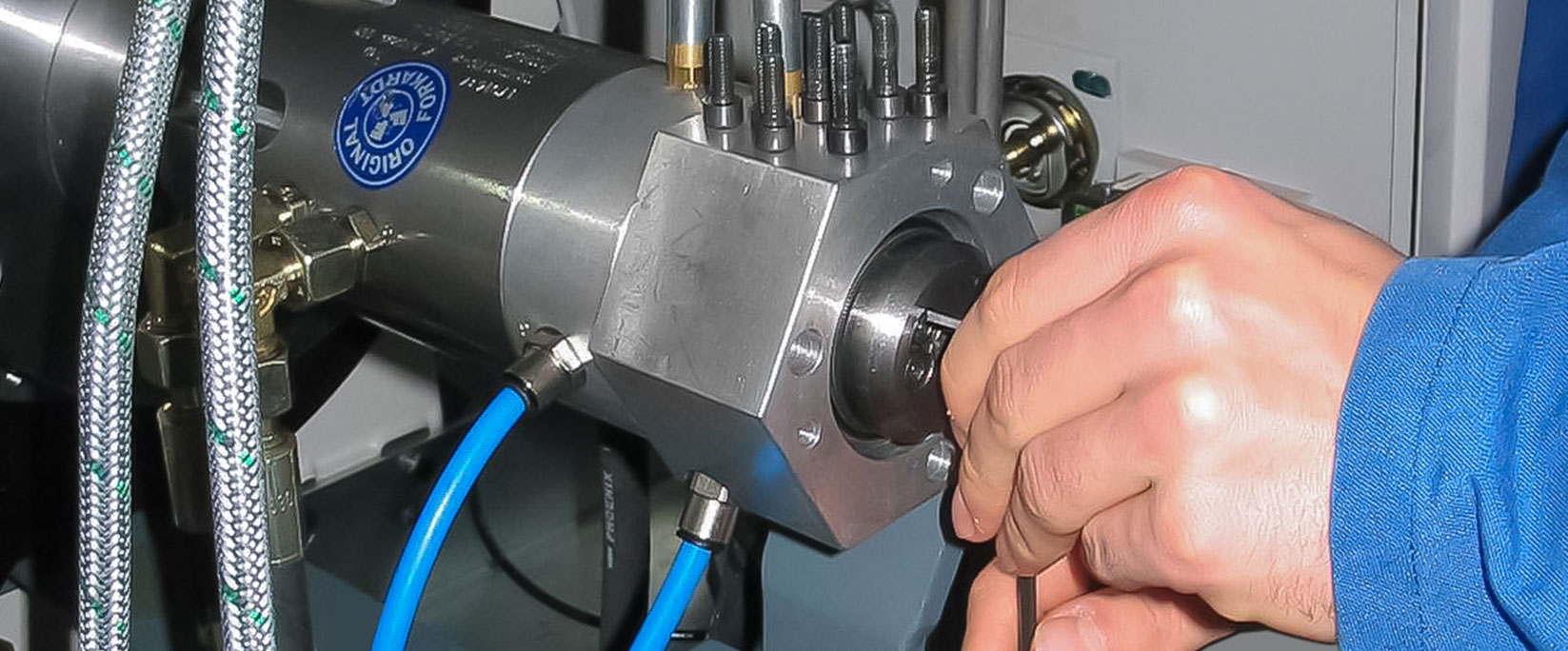

Picture 725

The N.A. Woodworth diaphragm chuck design is based on simplicity. A diaphragm chuck works similar to the action of an oil can bottom. No sliding parts; no friction, no wear! It operates by a simple flexing action, assuring consistently controlled concentrically.

The dovetail jaw design includes a unitized diaphragm assembly, self contained air cylinder, face plate adapter, rotary slip coupling, and installation instructions.

swipe to view full menu

All information is subject to change without notice swipe to view full menu

| Technical Data | |||||||||||

| Catalog No. | SC500 | SC501 | SC700 | SC701 | SC708 | SC801 | SC100 | SC101 | SC1301 | SC1701 | |

| O.D. Diameter | [mm] | 138 | 138 | 175 | 175 | 175 | 212 | 251 | 251 | 327 | 429 |

| No. of Jaws | 3 | 3 | 4 | 4 | 3 | 6 | 6 | 6 | 6 | 6 | |

| Movement Per Jaw | [mm] | 0.23 | 0.23 | 0.23 | 0.23 | 0.23 | 0.25 | 0.25 | 0.36 | 0.41 | |

| Part Range | [mm] | 9.5 - 76.2 | 9.5 - 76.2 | 12.7 - 101.6 | 12.7 - 101.6 | 12.7 - 101.6 | 54.0 - 139.7 | 50.8 - 177.8 | 50.8 - 177.8 | 88.9 - 254.0 | 127.0 - 355.6 |

| Max. Clamping Pressure | Single | 1050 | 1050 | 1800 | 1800 | 1800 | 2400 | 3800 | 3800 | 6800 | 12300 |

| Max. Clamping Pressure | Double | 2100 | 2100 | 3600 | 3600 | 3600 | 4800 | 7600 | 7600 | 13600 | 24600 |

| Weight (with jaws) | [Kg] | 6.83 | 7.26 | 10.43 | 11.34 | 10.88 | 17.24 | 23.13 | 24.5 | 43.54 | 89.81 |