Tru-Change Precision Coupling Rings

Tru-Change coupling rings offer a low profile, self-centering solution where fast changeover is required. The unique coupling design allows for high torsional loads to be applied to the workpiece, during the process. Forkardt offers this design where customers may utilize more than one workholding device, per spindle. Tru-Change rings are comprised of the Receiver and the Carrier. The Receiver is the ring that will mount to your machine spindle. The carrier(s) will then mount to your workholding devices. The number of workholding devices matched to one spindle, is unlimited. The system is designed to provide a matched set of rings in order to deliver optimal repeatability. Rings are manufactured utilizing masters, so that in-field replacement is available without interruption to your operations.

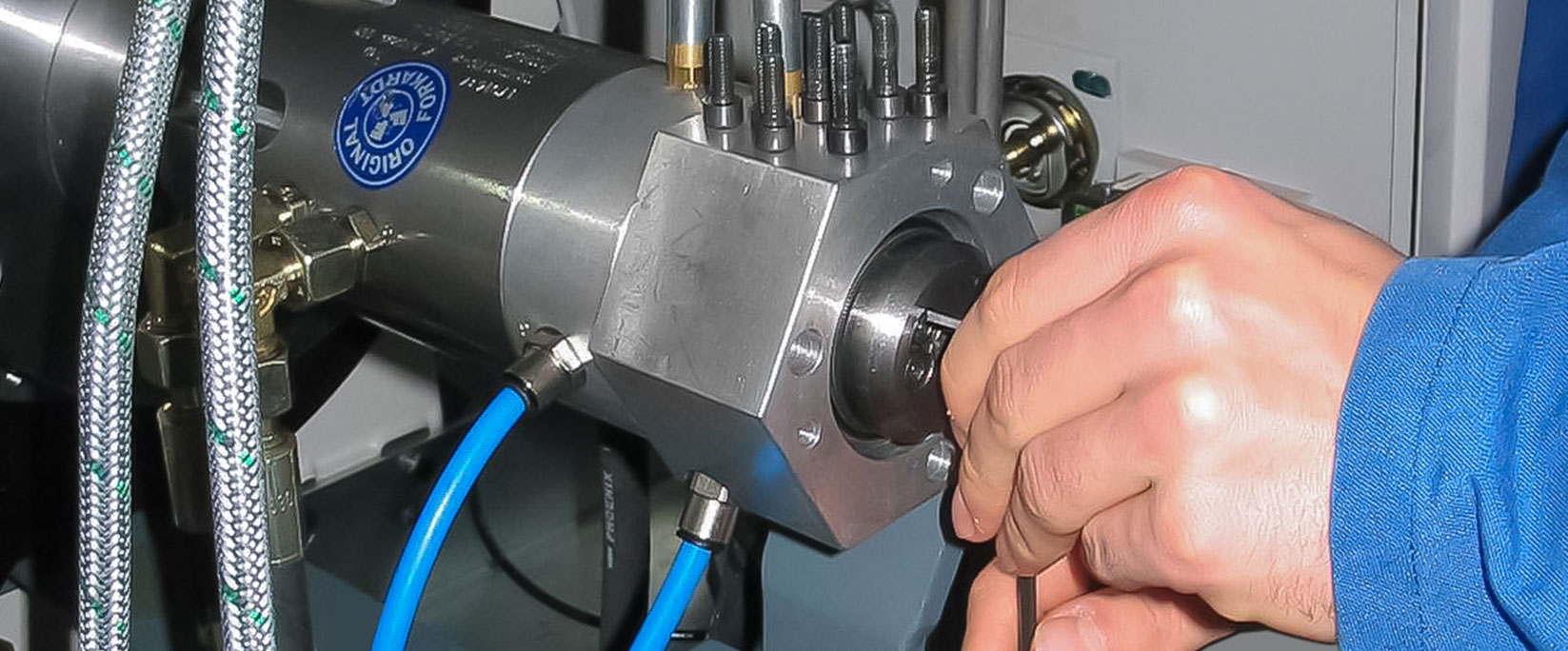

Forkardt offers both a manual and a fully automated system. The manual system will utilize a series of 3 or 6 bolts to secure the system in place. The fully automated system will require a dual acting (Duplex) cylinder to be added to the machine. With the cylinder in place, changeover of workholding devices can be fully automated. Rings can range from 3” (76mm) up to 21” (530mm). Forkardt has utilized this design for chucks up to 22” (560mm).